Safety Observation

Safety Observation

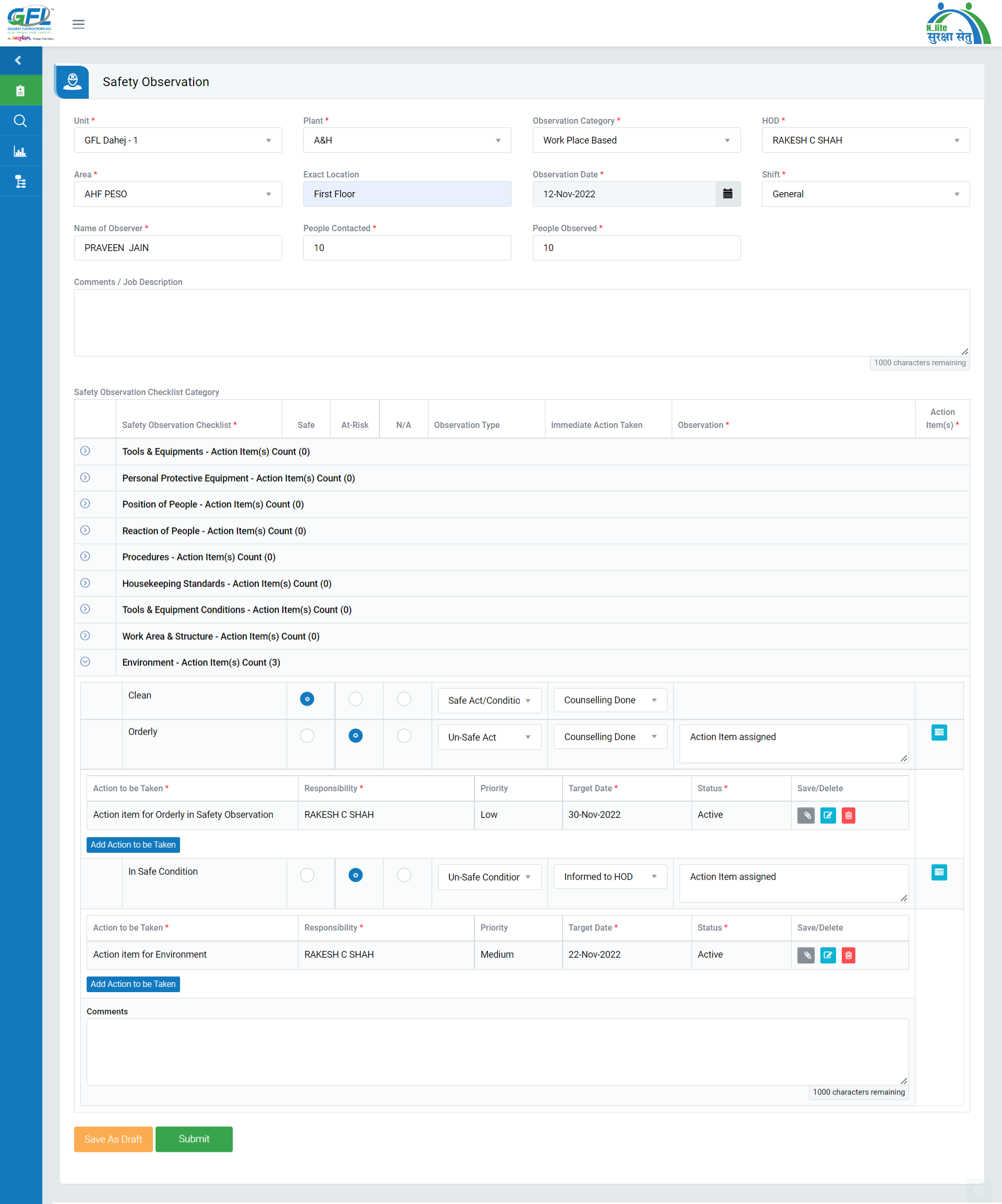

Objective:It allows user to report Safety Observation / behaviour based safety observation program and take action against it if assigned to him/her in the system.

Image 1

- Login as any system user and navigate to Safety Observation | Safety Observation screen.

- To initiate or report or request Safety Observation provide required details in the enabled fields

- Unit - Default unit will be the system user’s configured unit (Auto-Select).

- Plant - Select the Plant / Project in which Safety Observation need to be reported.

- Observation Category - Based on selection of type of Safety Observation, checklist will be populated.

- HOD - Head of the Department will be selected automatically by default as per the plant’s Plant HOD configuration (Auto-Select).

- In case if there are more than one plant HOD in selected plant, System allows you to select the required HOD.

- Area - Select the Area, where Safety Observation need to be conducted.

- Observation Date - By default, current date will be the observation date

- System allows user to select past date and current date only. Doesn’t allows to select future date.

- If you want to clear the selected random date, click on “clear” button or “Today “ button to clear field or select current date respectively.

- Shift - Select the shift , when Safety Observation need to conducted.

- Name of the Observer -

- By default, the observer name will be the Login System User name

- To change observer name, clear the field and search for the required observer and select.

- Can search using name and employee code

- Auto complete field - displays matched names of the observer on entering first 3 letters.

- People Contacted & People Observed - provide no of people observed and contacted

- Comments - provide comments or remarks if need to be entered any thing like instructions.

- Optional

- Safety Observation Check List - Based on the type of observation , select the required Safety Observation among displayed checklist.

- Safety Observation category and check list can be configured by admin.

- Type of Observation “Unsafe Act”, Unsafe Condition” can be selected from the drop down list.

- When barrier is “At-Risk”, action taken(select), comments and CAPA (Action Item) is mandatory.

- Action Item (CAPA) will be enabled after clicking on ‘At-Risk’ barrier only.

- Click on checklist | Select any one category | Click on At-risk

- CAPA can be assigned on multiple category individually.

- Action Items Count - Displays the count of CAPA’s assigned on single category.

- Once record is saved, action item will show or get notified on responsible persons (Respective HOD)“For Your Action”.

- Click on checklist | Select any one category | Click on At-risk

- Attachments - System allows user to upload any document file or photos etc.. if required.

- Optional

- Max Limit : 10 uploads only

- Click on “Save” button to save the Safety Observation.

- If user need to make any changes after some confirmations can save the record as “Save as draft” and confirm/save the Safety Observation later.

- After saving the record, System generates the unique report number for the Safety Observation reported

- Report No Format - GFLD1/A&H/SO/2022/1476 (Unit/Plant/Module/Year/Serial No)

Note :

- The fields marked with * are mandatory to be filled.